Your one-stop destination for high-quality welding solutions. Trust A.Alimohamed for all your welding needs and unlock a world of possibilities in metal fabrication. Weld with confidence, weld with precision – choose excellence with us!

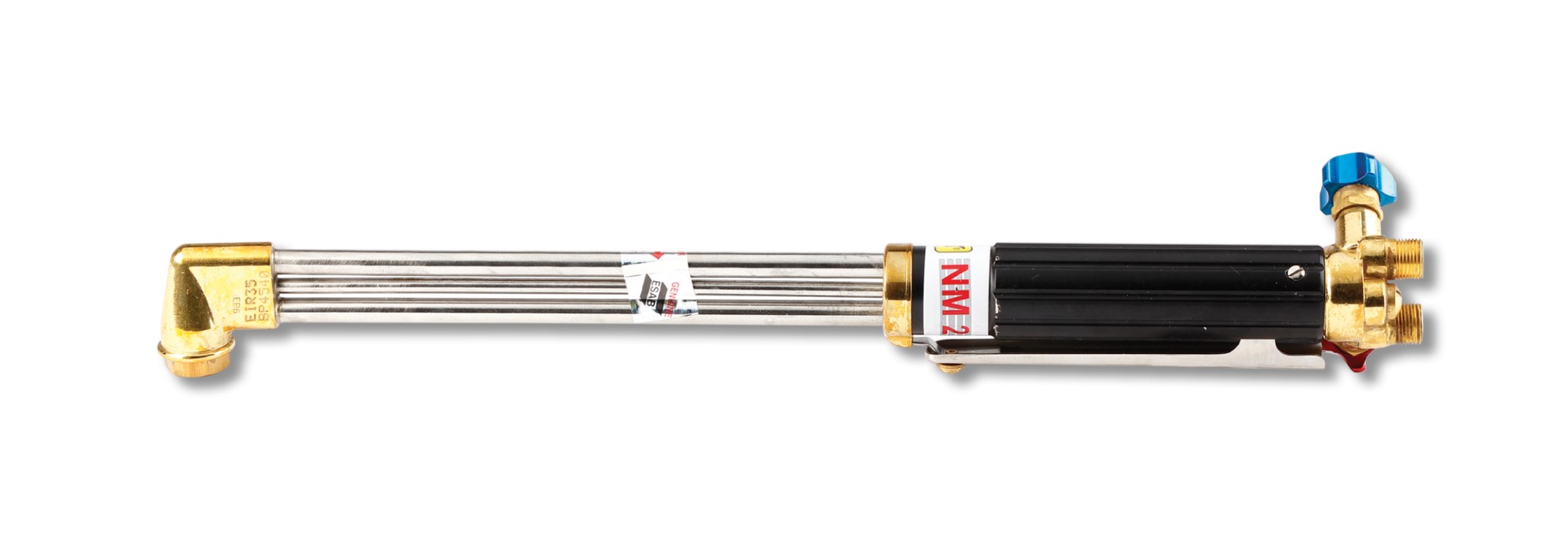

Gas Cutting: Gas cutting is a process used to cut metals with precision and efficiency. It involves the use of a gas cutting torch, typically fueled by a combination of oxygen and a fuel gas such as acetylene. The torch produces a high-temperature flame that melts the metal at the cutting point, while a stream of oxygen blows away the molten metal, resulting in a clean and precise cut. Gas cutting is widely employed in fabrication shops, construction sites, and industrial maintenance for cutting metal plates, pipes, and structural components.

Gas Welding: Gas welding, also known as oxy-fuel welding (OFW), is a welding process that utilises a gas flame to generate the heat required for melting the base metal and the welding rod. Similar to gas cutting, gas welding employs a gas welding torch fueled by a combination of oxygen and a fuel gas such as acetylene. The torch produces a controlled flame that heats the workpiece and the filler rod, allowing them to fuse together to form a strong weld joint. Gas welding is commonly used for joining thin metal sheets, repairing castings, and brazing applications.

For the process of Gas Cutting & Gas Welding, we need to use equipment like a Gas Regulator, Gas Cutting Torch or Gas Welding Torch, Gas Hoses, Flashback Arrestors and Gas Nozzles. These processes use Oxygen and Acetylene together and as a result, are very hazardous. Care must be taken in using the right products and wearing adequate PPE.

Warning: Undefined variable $selectedOtherProducts in /home/madhuagencies/alimohd.com/wp-content/themes/ali-mohamad/template-parts/related-products.php on line 14

Warning: Undefined variable $selectedOtherProducts in /home/madhuagencies/alimohd.com/wp-content/themes/ali-mohamad/template-parts/related-products.php on line 14